What is a Cable Gland?

Cable Glands - What Are They?

A cable gland (more often known in the U.S. as a cord grip, cable strain relief, cable connector or cable fitting) is a device designed to attach and secure the end of an electrical cable to the equipment. Cable Glands address an essential requirement in cable management planning and implementation. Their foremost purpose is to grip and seal electrical cables where they pass through a dividing barrier, such as upon entry to a piece of equipment or where they pass through a bulkhead or panel. This is achieved by gripping either the outer sheath of the cable or the armour wire, or by a combination of the two. Cable glands are available in countless designs and features but these can be distilled down to four essential functions.

- Sealing - the ability to provide a barrier against ingress of dust, liquid or gas.

- Retention - the ability to secure and hold the cable in place, commonly know as ‘pull out’ resistance.

- Continuity - the ability to safely carry a peak short circuit current.

- Environmental Protection - the ability to protect against environmental attack, from corrosive or explosive liquids and gasses to ultraviolet exposure.

How Do Cable Glands Work

Cable Glands consist of multiple threaded parts which fit together to grip the cable and secure the gland assembly and cable to a piece of equipment or panel. The number of parts varies depending on the application and the required level of protection.

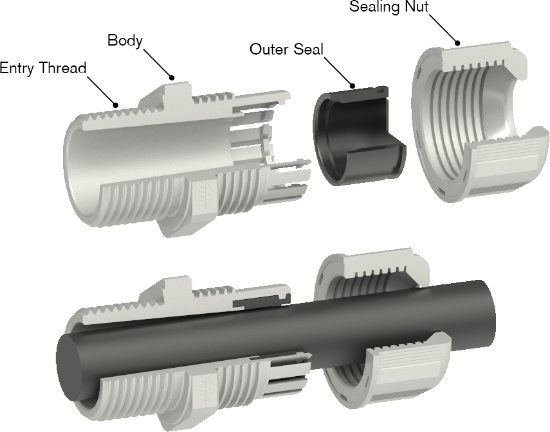

Firstly let's look at an example of a nylon ‘stuffing gland’.

Perhaps the simplest type of gland, this comprises a body section, an outer sheath seal and a sealing nut. The complete assembly is secured to the equipment or panel via the threaded entry part; this can be threaded directly into the equipment if it has an existing receiving thread, or secured with a locknut if a blank hole. The cable can then be passed through the assembled gland and the sealing cap tightened, compressing the inner seal and securing the cable in place. This also provides an environmental seal around the outer sheath.

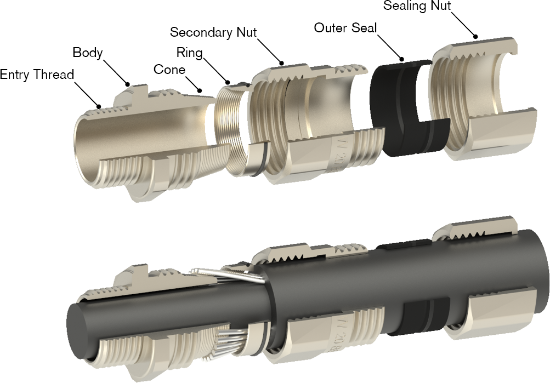

Our second example is a brass CW type Steel Wire Armour gland. This gland is slightly more complex, because it needs to provide an additional connection to the cable armour, however it shares the same fundamental design. The entry thread of the body is used to secure the whole assembly to the equipment. A secondary threaded nut which houses a cone-and-ring assembly secures the cable armour to the gland and finally once again a sealing nut secures and provides an environmental seal against the outer sheath.

There are several variations on this theme but nearly all cable glands work along this fundamental principal of a threaded entry assembly that connects to the equipment and additional threaded nuts which secure the cable to the assembly. These may provide additional seals on both the inner and outer sheath, allow for connection to braided cables, special EMC connections or increased safety for hazardous areas.

For a complete breakdown of the most common types of glands stay tuned for our upcoming article on How To Use Cable Glands Article [LINK]